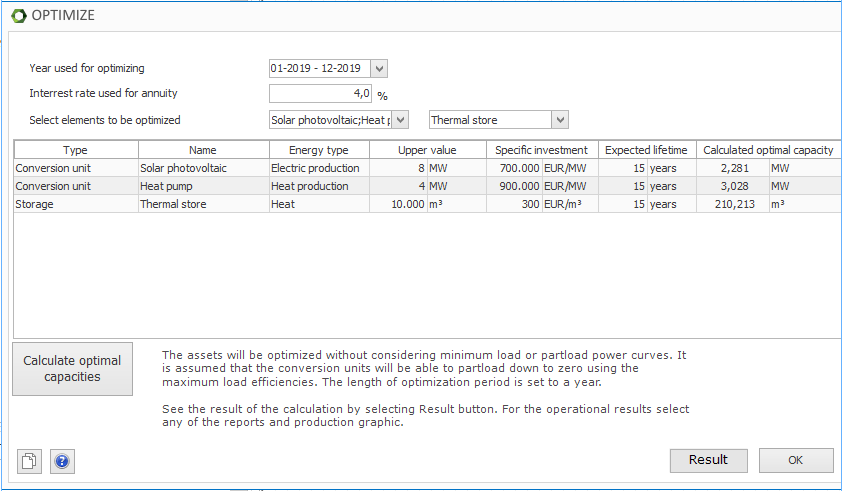

OPTIMIZE

OPTIMIZE is the newest module which allows you to optimize the size of PV, CHP, heat pump, storage or any new asset you include in your modelling.

-

Calculate The Annuity Cost

Calculate The Annuity Cost

Based on the inputs in OPTIMIZE, energyPRO calculates an annuity cost, which is connected

to the size of the asset. energyPRO

will find the optimal size and operation based

on the annuity cost, operational cost as well

as income and technical conditions such as

demands and transmission restrictions. -

Fast Results

Fast Results

In the OPTIMIZE, energyPRO calculates the

optimal sizing together with the optimal operation in one calculation, which gives a

fast result. -

User-Friendly Interface

User-Friendly Interface

Easily select the assets, planning period, specific investments, expected lifetime and interest rate.